- 您现在的位置:买卖IC网 > Sheet目录286 > 22N78-311P.1001 (Portescap)MOTOR BRUSHED DC 9W 12V 7300RPM

�� �

�

�

�Features� of� Ironless� Rotor� DC� Motors�

�The� rotor� of� a� conventional� iron� core� DC� motor� is� made� of� copper� wire� which� is� wound� around� the� poles� of� its� iron�

�core.� Designing� the� rotor� in� this� manner� has� the� following� results:�

�?� A� large� inertia� due� to� the� iron� mass� which� impedes� rapid� starts� and� stops�

�?� A� cogging� effect� and� rotor� preferential� positions� caused� by� the� attraction� of� the� iron� poles� to� the� permanent� magnet.�

�?� A� considerable� coil� inductance� producing� arcing� during� commutation.� This� arcing� is� responsible� on� the� one� hand� for� an�

�electrical� noise,� and� on� the� other� hand� for� the� severe� electro—erosion� of� the� brushes.� It� is� for� the� latter� reason� that� carbon�

�type� brushes� are� used� in� the� conventional� motors.�

�A� self� supporting� ironless� DC� motor� from� Portescap� has� many� advantages� over� conventional� iron� core� motors:�

�?� high� torque� to� —� inertia� ratio�

�?� absence� of� preferred� rotor� positions�

�?� very� low� torque� and� back� EMF� variation� with� armature� positions�

�?� essentially� zero� hysteresis� and� eddy� current� losses�

�?� negligible� electrical� time� constant�

�?� almost� no� risk� of� demagnetization,� thus� fast� acceleration�

�?� negligible� voltage� drop� at� the� brushes� (with� multiwire� type� brushes)�

�?� lower� viscous� damping�

�?� linear� characteristics�

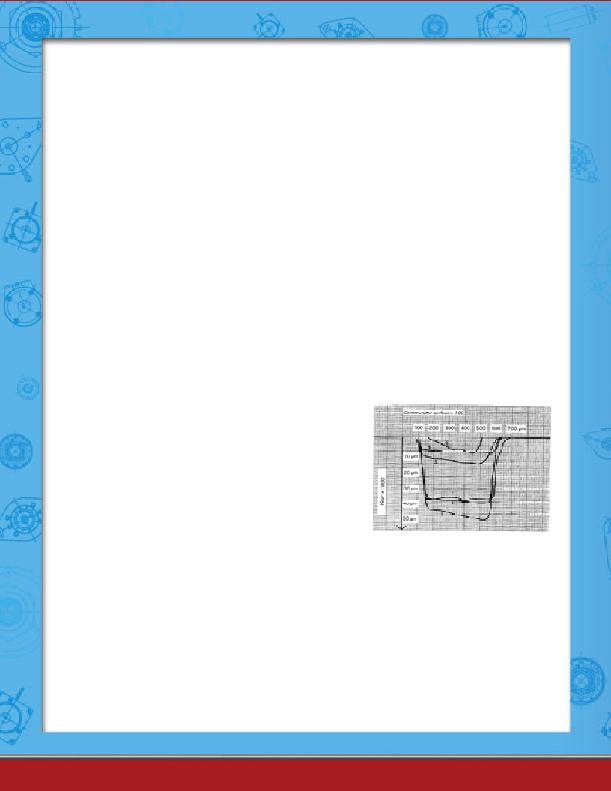

�REE� System� proven� to� increase�

�motor� life� up� to� 1000� percent�

�The� two� biggest� contributors� to� the� commutator� life� in� a� brush� DC� motor�

�are� the� mechancical� brush� wear� from� sliding� contacts� and� the� erosion�

�of� the� electrodes� due� to� electrical� arcing.� The� superior� surface� finish,�

�commutator� precision� along� with� material� upgrades� such� as� precious�

�metal� commutators� with� appropriate� alloys� has� helped� in� reducing� the�

�mechanical� wear� of� the� brushes.� To� effectively� reduce� electro� erosion�

�in� while� extending� commutator� life� Portescap� innovated� its� proprietary�

�REE� (Reduced� Electro� Erosion)� system� of� coils.� The� REE� system� reduces�

�the� effective� inductivity� of� the� brush� commutation� by� optimization� of� the�

�mutual� induction� of� the� coil� segments.� In� order� to� compare� and� contrast�

�the� benefits� of� an� REE� system� Portescap� conducted� tests� on� motors�

�with� and� with� out� REE� coil� optimization.� The� commutator� surface� wear�

�showed� improvements� ranging� from� 100� -300� percent� as� shown� in� Figure�

�5.� Coils� 4,� 5� and� 6� are� REE� reinforced� while� 1,� 2� &� 3� are� without� REE�

�reinforcement.�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

22P6868

PANEL INNER 68X68" WHITE

22XSR-36S

CONN RCPT XSR 22POS .6MM IDC

2320018

CONVERTER DC-DC 12-24/5-15VDC 2A

23A640-I/ST

IC SRAM 64KBIT 20MHZ 8TSSOP

23K256T-E/ST

IC SRAM 256KBIT 20MHZ 8TSSOP

23K640-E/P

IC SRAM 64KBIT 20MHZ 8DIP

23KM-K743-99V

MOTOR STEP UNI 56MM SQ 24V DL

24AA00-I/PG

IC EEPROM 128BIT 400KHZ 8DIP

相关代理商/技术参数

22N78313P1001

功能描述:有刷 DC 标准 电机 10000 RPM 12W 9VDC 制造商:portescap 系列:22N78 Athlonix 零件状态:有效 类型:直流电机 功能:标准 电机类型:有刷 电压 - 额定:9VDC RPM:10000 RPM 扭矩 - 额定值 (oz-in / mNm):2.05 / 14.5 功率 - 额定值:12W 编码器类型:- 大小/尺寸:圆形 - 0.866" 直径(22.00mm) 直径 - 轴:0.059"(1.50mm) 长度 - 轴和轴承:0.295"(7.50mm) 安装孔间距:0.670"(17.00mm) 端子类型:焊片 特性:- 齿轮减速比:- 扭矩 - 瞬时最大值?(oz-in / mNm):- 工作温度:-30°C ~ 85°C 认可:- 重量:0.117 磅(53.07g) 标准包装:10

22N78-319P.1001

功能描述:MOTOR BRUSHED DC 9W 6V 8700RPM RoHS:是 类别:电机,螺线管 >> 电机 - AC,DC 系列:22N78, Athlonix 标准包装:1 系列:OMNUC G 类型:伺服 AC 电压 - 额定:200VAC RPM:1000 RPM 直径 - 主体:6.93"(176.00mm) 直径 - 轴:1.38"(35.00mm) 长度 - 轴和支架:3.15"(80.00mm) 安装孔间距:7.87"(200.00mm) 特点:绝对式编码器,键 端接类型:连接器 转矩 - 运行(oz-in / mNm):4021.8 / 28400 转矩 - 启动状态 (oz-in / mNm):- 转矩 - 停滞状态 (oz-in / mNm):- 齿轮减速比:无 电压范围:- 功率(瓦特):3kW 重量:55 磅(24.9kg) 其它名称:R88MG3K010TS2

22NA005G

制造商:未知厂家 制造商全称:未知厂家 功能描述:Industrial Control IC

22NA010G

制造商:未知厂家 制造商全称:未知厂家 功能描述:Industrial Control IC

22NA015G

制造商:未知厂家 制造商全称:未知厂家 功能描述:Industrial Control IC

22NA104

制造商:HARVARD INDUSTRIES INC 功能描述:

22NA1-632

制造商:GREER (SPS) 功能描述:

22NA17A-62

制造商:Esna Technologies 功能描述: